RoNaK

Mining Industrial Corporation

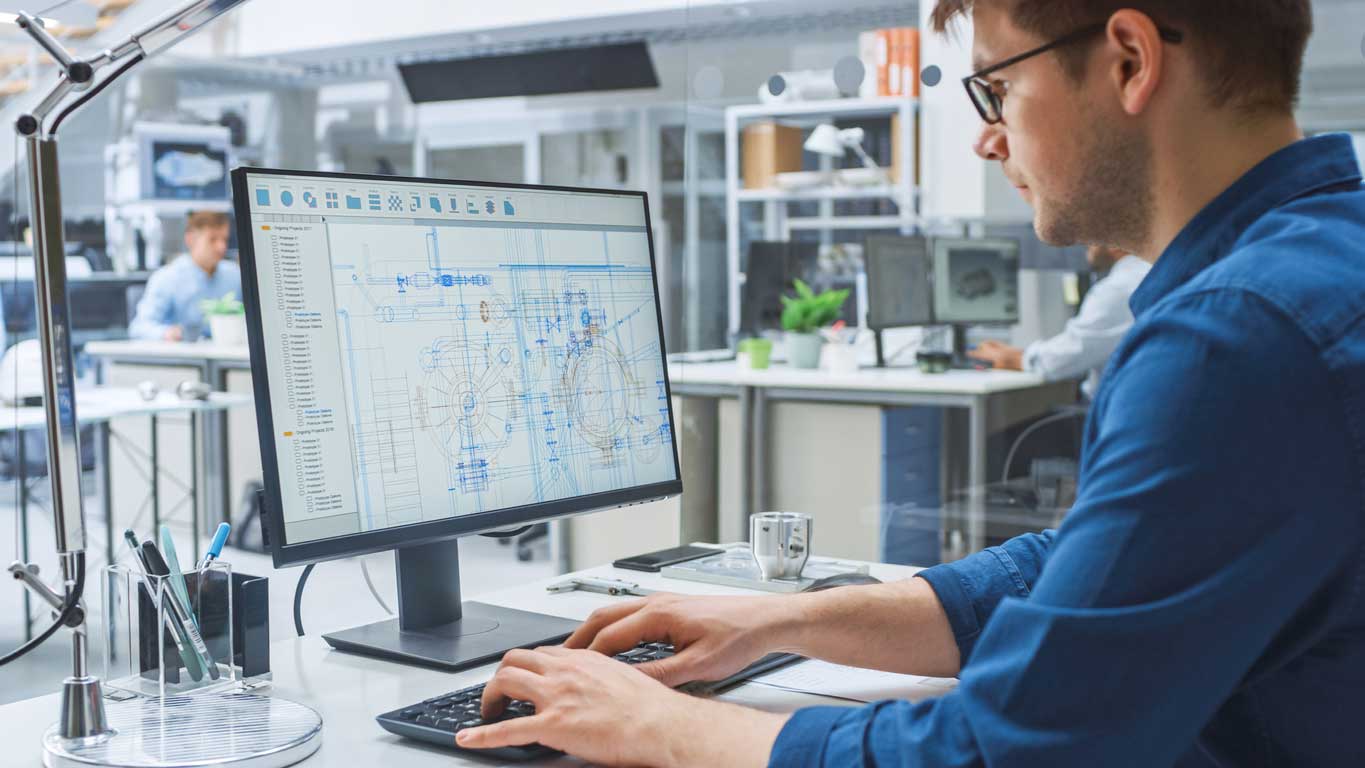

Practical Solutions forEngineering ProcurementProject Management

What We Do

In RoNak Engineering

Based on our knowledge, expertise, and experiences we have concentrated on mining industrial projects. We consider value engineering methods in our solutions in order to optimize customers' objectives in various areas such as engineering, procurement, construction, project management, ...

Our Market

Iron Ore

Iron Ore  Pelletizing & Steel Making

Pelletizing & Steel Making  Copper, Molybdenum & Gold

Copper, Molybdenum & Gold  Lead & Zinc

Lead & Zinc  Nonmetallic Mineral

Nonmetallic Mineral  Ferroalloys

Ferroalloys  Material Handling Systems

Material Handling Systems  Mechanized Mining Systems

Mechanized Mining Systems  Water Recovery

Water Recovery  Optimization Of Plants

Optimization Of Plants

Iron Ore

Iron ore is the basic raw material for iron and steel making. Hematite and magnetite are the most prominent of the iron ores which are found. Based on the magnetic susceptibility values, iron ore can be divided into two groups, namely strongly magnetic iron ores, that is magnetite, and weakly magnetic iron ores (oxidized iron ores) hematite. The emphasis is on development of cost-effective flow sheets to beneficiate the low-grade iron ores to produce concentrate suitable for blast furnace, sinter or pellet making.

Learn More

Pelletizing & Steel Making

Pelletizing is a process that involves mixing very finely ground particles of iron ore fines with additives like bentonite and then shaping them into near oval/spherical balls having sizes in the range of 8 mm to 16 mm in diameter with a pelletizer and hardening the balls by firing with a fuel. It is an agglomerating process of converting iron ore fines into ‘uniformed sized iron ore pellets’ which can be charged directly into a blast furnace (BF) or into a vertical furnace or rotary kiln normally used for the production of direct reduced iron (DRI).

Learn More

Copper, Molybdenum & Gold

The most common types of copper ore are copper oxide and copper sulfide. Copper oxides are more abundant near the surface, but are considered low-grade ore. Copper sulfide ore, which accounts for 80% of the copper resource, is the major source of metallic copper. Copper processing is a complicated process that begins with the mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes.

Copper and molybdenum are frequently found together as sulfides in ore bodies throughout the world, and are customarily removed from these ore bodies and separated from each other by differential froth flotation.

Learn More

Lead & Zinc

Both lead and zinc occur together in nature due to their similar precipitation condition. Though lead-zinc is found in either sulfide or oxide or mixed (sulfide-oxide) complex form, it is primarily beneficiated from sulfide deposits. Lead-zinc ores are treated with different beneficiation techniques according to their mineralogical and textural characteristic. Generally, froth flotation is used to treat mined lead-zinc ore. In some places, gravity concentration is used for pre-concentration/beneficiation purposes.

Learn More

Nonmetallic Mineral (Coal Washing)

Due to its complexities, Coal washing is different from the processing of other minerals. Not only in the reconnaissance stage but also in the selection of different washing methods and process design, the usual processing methods cannot be used in coal washing.

Learn More

Ferroalloys

An alloy is a mixture or solid solution composed of metals. Similarly, Ferroalloys are a mixture of Iron with a high proportion of other elements like manganese, aluminum, or silicon. Alloying improves physical properties like density, reactivity, young’s modulus, electrical and thermal conductivity, etc.

The ferroalloys industry is very closely related to the iron and steel industry since ferroalloys are used extensively in steelmaking, and in iron or steel foundries.

Learn More

Material Handling Systems

Material handling is an inseparable part of processing plants. At the beginning, after mining in the mine, and at the end, when the product is to be transported and stored, material handling plays a key role in the efficiency and profitability of processing plants. The primary function of this system is to continuously transport and supply bulk material to the units in the processing plants. Another common goal is the storage and blending of materials.

Learn More

Mechanized Mining Systems

Mine mechanization, especially the mechanization of underground hard rock mines provides a large potential for reduced costs and improved profitability. It appears that the development of mechanization for fundamentally new mining systems will require complex joint ventures involving mining companies, equipment suppliers, governments, and academic partners working together on a long-term commitment. These technical joint ventures will require long-term commitments of capital to produce the technology that will be required for mechanizing the underground mines of the future.

Learn More

Water Recovery

In recent times, mining plant investors have shown a higher interest in the dewatering and filtration sectors of beneficiation plants. This is due to growing concerns about water scarcity and environmental impact. Countries facing water stress, as well as those with strong environmental policies, consider the amount of water consumed in mineral projects as a crucial factor in feasibility studies. In the past, due to issues related to the quality of the product and the possibility of its convenient transportation, only the dewatering and filtration of the product was important, but nowadays, the dewatering of tailings is important too.

Learn More

Optimization Of Plants

Mineral processing plants are crucial for extracting valuable minerals from ores. To improve the efficiency and profitability of these plants, advanced techniques, and optimization methods are essential. Optimization methods in mineral processing plants can improve their efficiency, reduce costs, and increase profitability.

Learn MoreServices

Major Projects

JALAL ABAD IRON ORE CONCENTRATE PLANT

- Client: Fakoor Sanat Tehran Co.

- Product: Iron Ore Concentrate

- Production Capacity: 620,000 TPY

- Project Type: EPC

- Province: Kerman

Concentrate Quality Improvement of Line4

- Client: Golgohar Mining & Industrial Co.

- Product: Iron Ore Concentrate

- Production Capacity: 2,650,000 TPY

- Project Type: Consultant & Supervision

- Province: Kerman

IMPLEMENTATION OF BAHABAD IRON ORE CONCENTRATE PLANT (NO.1)

- Client: Fakoor Sanat Tehran Co.

- Product: Iron Ore Concentrate

- Production Capacity: 1,300,000 TPY

- Project Type: EPC

- Province: Yazd

MESKAVAN COPPER CONCENTRATE PLANT

- Client: Meskavan Co.

- Product: Copper Concentrate

- Production Capacity: 5,500 TPY

- Project Type: EP

- Province: Khorasan Razavi

CENTRAL ALBORZ COAL WASHING PLANT

- Client: Iranian Production And Supply Company (IMPASCO)

- Product: Coal

- Production Capacity: 350.000 TPY

- Project Type: Engineering

- Province: Mazandaran

IMPLEMENTATION OF TAJ KOH LEAD AND ZINC ORE BENEFICIATION PLANT

- Client: Aria Fateh Holding

- Product: Lead & Zinc Ore

- Feed Capacity: 100,000 TPY

- Project Type: EPC

- Province: Yazd

KAVYAN GOHAR HEMATITE BENEFICIATION PLANT

- Client: KAVYAN GOHAR Co.

- Product: Iron Ore Concentrate

- Production Capacity: 1,900,000 TPY

- Project Type: Engineering

- Province: Kerman

Our Projects

40+ Projects in mining industry

0

EPC

0

E-MC

0

Engineering

0

Consulting